Vörulýsing

This is a well designed planer thicknesser, especially suited to the trade workshop. Constructed from cast iron and heavy gauge welded steel, it is robust and will withstand heavy usage on a daily basis. The cast iron surfacing tables have heavy ribbing underneath to maintain flatness and, unusually, both tables are completely adjustable to the blades to avoid sniping. The tables hinge independently and have up-stop latches to hold them securely when thicknessing. The thicknessing table is easy to adjust with a smooth mechanism and it has a position lock which prevents any movement. There is a power feed engagement lever for use when thicknessing; the 5m/min feed speed ensures a smooth, even finish. When surface planing, the long rigid alloy fence supports your work securely, the fence being easily adjustable with stops for 90° and 45°. Brackets are mounted on the rear of the machine to store the fence when not in use. Chip extraction is via a hinging flip-over hood which is electrically interlocked for safety.

This version is fitted with a spiral blade cutter block. This uses 15mm x 2.5mm 4-sided TCT spur type cutters, 44 in all arranged over four rows. These cutters are unique in that the edges are machined to a radius of 102mm; this coupled with how they are set on the block means that a shear type cut is achieved. There are several advantages of this type of cutter block. Durability: each edge will last around 10-20 times longer than a HSS knife and you have four edges per cutter. Noise: spiral cutter blocks are notably quieter in use, up to 50% with some timbers. Power: because of their shear type cutter action, the power saving can be as much as 30%, meaning much less strain on the machine and lower running costs. Your extraction will be more efficient because of the even shape of the chips, packing more into the waste sack. The spiral blade cutter block versions are also supplied with digital height indication of the thicknessing table.

If your work involves machining difficult, abrasive timbers, or large batch production with sanding as a finishing procedure, then this system is unbeatable. And the finish is silky smooth, without the traditional fine lines across the board.N.B. 16A supply required, type C breaker recommended.

Key Features

- Trade rated planer thicknesser substantially constructed from cast iron and welded steel

- Cast iron tables and tilting alloy fence offer exceptional accuracy and stability

- Spiral cutter block gives a very clean finish to the work combined with long cutter life

- Uses 44, 15mm x 2.5mm four sided “shear cut” tungsten cutters

- Pivoting dust extraction hood operates in thicknessing and surfacing modes

- Both tables are adjustable and electrically interlocked for safety

- Extended support roller on thicknessing table

tækniupplýsingar:

| Cutter Type | TCT Spiral Cutter Block |

|---|---|

| Cutterblock Diameter | 70 mm |

| Cutterblock Speed | 4,800 rpm |

| Dust Extraction Outlet | 100 mm |

| Feed Speed | 5 m/min |

| Length of Table | 1,100 mm |

| Max Depth of Cut Planer | 3.0 mm |

| Max Depth of Cut Thicknesser | 2.0 mm |

| Max Planing Width | 260 mm |

| Max Thicknessing Capacity | 190 mm |

| Min Extraction Airflow Required | 1,000 m³/hr |

| Nett Weight | 182 kg |

| Number of Knives | 44 |

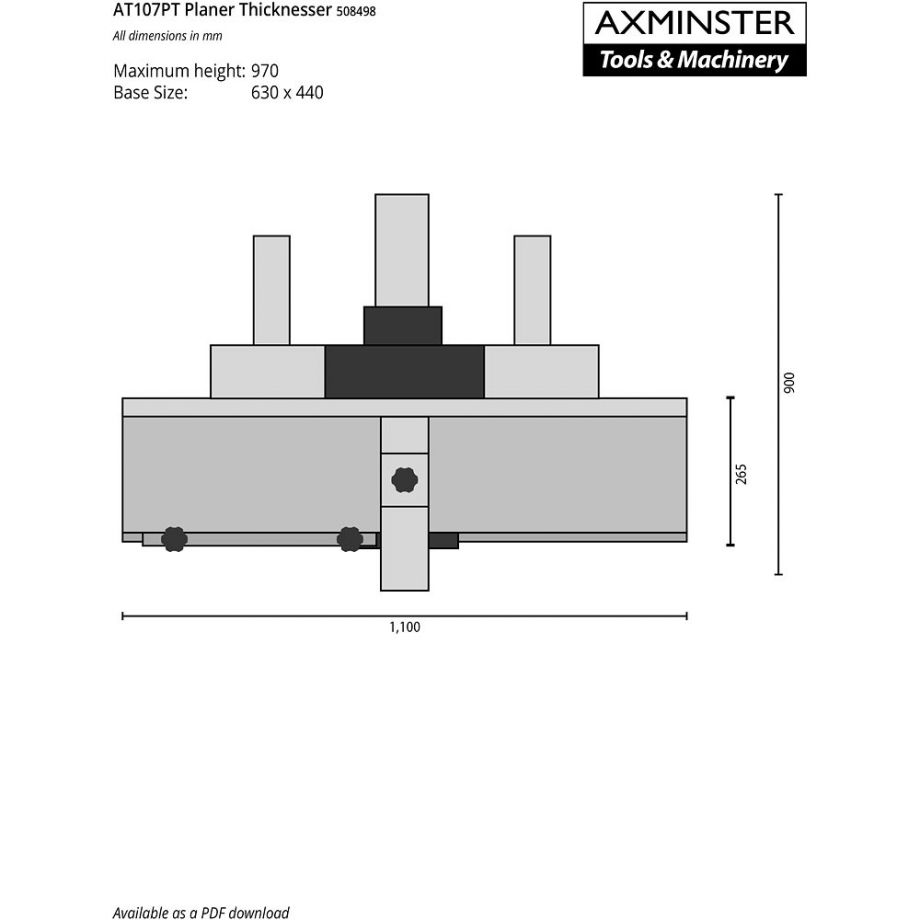

| Overall L x W x H | 1,100 mm x 660 mm x 940 mm |

| Power | 2.2 kW |

| Rating | Trade |

| Sound Power Level LWA [Uncertainty K] | 89 dB(A) [1.5 dB] |

| Voltage | 230 V |

Umsagnir

Það eru engar umsagnir komnar ennþá.